Table of Contents

What is a printhead?

A printhead is basically the heart of inject printer which is directly in charge of placing each ink drop on the substrate.

Inkjet printheads are miracle of modern engineering which are capable of positioning thousands of ink drops of different sizes in the required place. Several approaches are available for designing the printheads; however drop-on-demand is the most popular type.

Functionality of Printheads in Inkjet Printers

In the realm of modern printing technology, the term “printhead” often emerges as a pivotal component, wielding significant influence over the quality and precision of printed output. But what exactly is a printhead, and why is it hailed as the heart of inkjet printers? In this comprehensive guide, we delve into the intricacies of printheads, unraveling their importance and shedding light on their remarkable functionality.

Defining the Printhead

A printhead serves as the central apparatus within an inkjet printer, tasked with the crucial responsibility of depositing ink droplets onto the substrate, whether it be paper, fabric, or any other printable material. Acting as the conduit between digital design and tangible output, the printhead embodies the marriage of cutting-edge engineering and artistic expression.

Inkjet printheads stand as a testament to the marvels of modern engineering, exhibiting unparalleled precision and efficiency in their operation. Capable of orchestrating the precise placement of thousands of ink droplets, each varying in size and hue, inkjet printheads epitomize innovation in the realm of digital printing.

Function of the printhead in large format printers

In large format digital printers, printheads have nozzles that guide the ink droplets into the printing surface through small holes smaller than a hair diameter. They have a very crucial job as the quality level of the final product depends on the amount of ink is infused into the surface.

What does Picoliter measure in printhead?

it measures the volume of ink drop ejecting from the inkjet printhead. the size of the dot depends on the size of the droplet, so the smaller the droplet, the smaller the size.

Have you ever wondered how printers can make such tiny dots on paper to create pictures and text? Well, one important measurement in printing is called a picoliter. A picoliter is a very small unit used to measure the volume of ink droplets. It’s so tiny that you can’t even see it with your naked eye!

Examples of Picoliters

Imagine you have a droplet of ink. Now, think about dividing that droplet into one trillion equal parts. Each of those tiny parts is one picoliter! That’s how small a picoliter is.

Let’s put it into perspective with some examples:

Printing Photos:

When you print a photo, the printer uses picoliters to spray tiny droplets of ink onto the paper. The smaller the droplets (measured in picoliters), the finer the details in the picture will be. So, if a printer can produce droplets of, say, 2 picoliters, it can create very detailed and high-quality photos.

Text Documents:

Even when printing text documents, picoliters matter. The smaller the droplets, the sharper and clearer the text will appear on the paper. So, printers with smaller picoliter measurements are often used for printing documents where every word needs to be crisp and easy to read.

Color Accuracy:

In color printing, different colors are created by mixing various amounts of cyan, magenta, yellow, and black inks. Picoliters help ensure that the right amount of each color is deposited on the paper. For example, if you want to print a sky-blue color, the printer will use specific picoliter measurements of cyan and magenta to achieve the perfect shade of blue.

Applications of Picoliters

Understanding picoliters opens the door to a wide range of applications across various industries, where precise control over ink deposition is paramount. Here are some key areas where picoliter technology finds its application:

- Inkjet Printing: Picoliters play a crucial role in inkjet printing, where they determine the size of ink droplets ejected onto the printing substrate. Whether it’s printing photos, text documents, labels, or intricate graphics, printers utilize picoliter measurements to achieve optimal print quality, sharpness, and color accuracy.

- Biotechnology: In the field of biotechnology, picoliters are employed in techniques such as inkjet bioprinting and microarray spotting. These technologies enable the precise deposition of biological materials, such as cells, proteins, and DNA, onto substrates for various applications, including tissue engineering, drug discovery, and medical diagnostics.

- Microelectronics: Picoliters are utilized in the manufacturing of microelectronic devices, such as semiconductor chips and integrated circuits. Techniques like inkjet printing and aerosol deposition use picoliter-sized droplets to deposit conductive, insulating, or functional materials onto substrates with micron-scale precision, facilitating the production of miniaturized electronic components.

- 3D Printing: In the realm of additive manufacturing, picoliters contribute to the development of high-resolution 3D printing techniques. By controlling the size and placement of individual droplets, 3D printers can fabricate intricate and finely detailed objects with superior surface quality and dimensional accuracy.

- Materials Science: Picoliters find applications in materials science research, particularly in the deposition of functional coatings, thin films, and nanostructures. Techniques like inkjet printing and aerosol deposition enable the precise patterning and layering of materials at the micro and nanoscale, facilitating the development of advanced materials with tailored properties for various industrial and scientific purposes.

- Microfluidics: In microfluidic devices and lab-on-a-chip systems, picoliters are utilized to manipulate and control fluid volumes at the microscale. By precisely dispensing picoliter-sized droplets, researchers can perform a wide range of analytical and diagnostic assays, including DNA sequencing, immunoassays, and drug screening, within miniature and portable platforms.

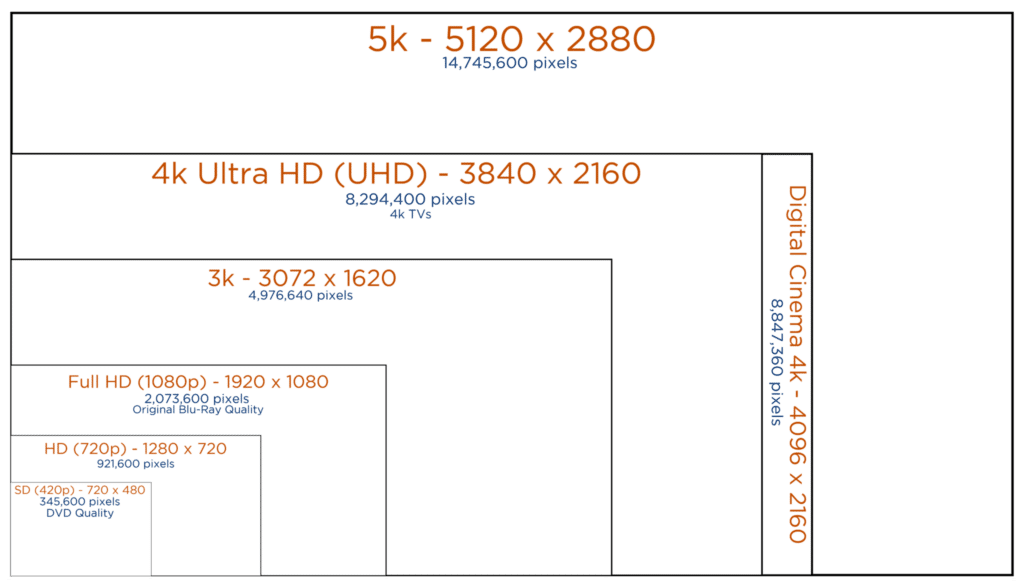

Resolution Quality in printhead

To judge the quality of the resolution we should consider the text samples not the graphic ones; obviously graphics always look much better than text. It is important to consider the paper materials as well; for example coated papers are expensive but the increase the quality of the print and they absorb too much ink compare to regular copy papers.

Resolution Quality: An Everyday Example

Imagine you’re sitting in a cozy café, flipping through a glossy magazine. As you browse through the pages, you notice a striking photograph of a vibrant sunset over a serene beach. The colors are vivid, the details crisp, and you feel as though you could almost step into the scene.

Now, what if I told you that the stunning clarity and lifelike quality of that image are all thanks to resolution?

In simple terms, resolution quality refers to the level of detail and clarity in an image, and it’s something you encounter every time you view a photograph, watch a video, or even scroll through your smartphone screen.

Let’s break it down further:

Pixels: The Building Blocks of Resolution

Think of resolution as a puzzle, with each piece representing a tiny element called a pixel. The more pixels you have, the clearer and more defined the image becomes. Imagine trying to assemble a puzzle with only a handful of pieces versus one with hundreds or even thousands – the difference in detail would be striking.

High vs. Low Resolution: Spotting the Difference

Consider two versions of the same photograph: one taken with a high-resolution camera and the other with a low-resolution camera. In the high-resolution version, you can see every grain of sand on the beach, every ripple in the water, and every hue in the sky with remarkable clarity. On the other hand, the low-resolution version appears blurry and pixelated, lacking the fine details that make the scene come to life.

Resolution Applications in Everyday Life

Resolution quality extends beyond photographs to encompass various aspects of our daily lives:

- Printing Documents: Even when printing documents, resolution quality matters. A document printed in high resolution will feature sharp text and crisp images, making it easier to read and more visually appealing.

- Watching Movies: When you stream a movie in high definition (HD) or even ultra-high definition (4K), you’re experiencing top-notch resolution quality. Every frame is packed with detail, allowing you to immerse yourself fully in the cinematic experience.

- Gaming: Gamers understand the importance of resolution when it comes to graphics quality. Playing a game in high resolution means seeing every texture, shadow, and character animation in stunning clarity, enhancing the overall gaming experience.

Thermal printheads

HP and Canon use thermal drop on demand which heats up the ink to the boiling point producing ink vapor which results in creating a bubble that pushes the ink drop through nozzle.

It’s important to mention that only water-based inks can only use this method. It’s very important to bring to the attention that recently HP has extended its latex inks applications which are water based and suitable for outdoor signage, as well as some textile applications.

Understanding Thermal Printheads

Imagine you have a special printer, like the one you might use at home or in an office, but this printer has a unique way of putting ink on paper. Instead of using traditional methods like spraying or pressing ink onto the paper, it uses something called a thermal printhead.

How Thermal Printheads Work?

Now, let’s dive into how this magical thermal printhead works. Picture a tiny, microscopic heating element inside the printhead. When you want to print something, this heating element gets really hot, almost to the point of boiling.

Next, there’s ink inside the printer. But it’s not just any ink – it’s a special kind that reacts to heat. When the heating element heats up, it causes the ink right next to it to boil and turn into vapor. This vapor creates a little bubble, kind of like a tiny balloon, which pushes the ink droplet out through a tiny hole in the printhead onto the paper.

Why Thermal Printheads Matter?

Now, you might be wondering why all this fancy technology matters. Well, one big reason is that it allows for really precise and detailed printing. Because the ink droplets are so tiny and controlled, you can get super sharp and clear images and text on your paper.

Water-Based Inks and Thermal Printheads

But here’s an important thing to note: Thermal printheads work best with a specific type of ink – water-based ink. This means that the ink used in these printers is mostly made up of water. This is because the process of heating the ink works best with water-based inks.

Example: HP’s Latex Inks:

Now, let’s talk about something cool that HP has done with their thermal printheads. They’ve developed a type of ink called latex ink. This ink is still water-based, but it’s special because it’s more durable and can be used for things like outdoor signs or printing on textiles, like clothes.

So, imagine you’re driving down the street and you see a huge billboard advertising the latest movie. That colorful and vibrant image was likely printed using HP’s latex inks with thermal printheads. It’s amazing how technology like this can bring big, bold designs to life in the world around us.

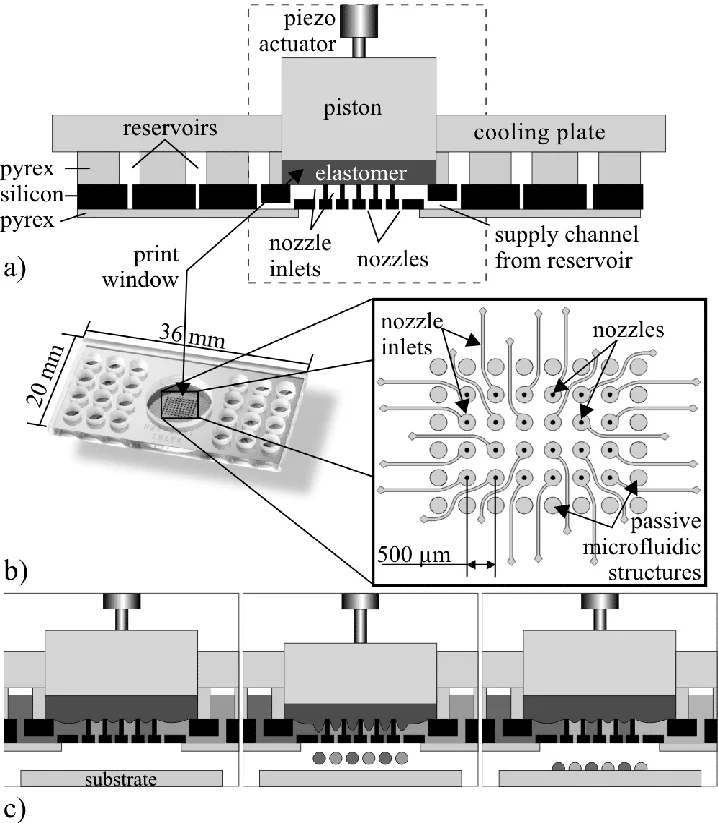

Drop on demand Piezo printheads

In this method the printhead has an ink chamber that pushes the ink out of the nozzles by the use of piezo electric charges and vibration. We can use this method with different types of inks such as aqueous, solvent and UV-curable. A piezoelectric technique is used in Epson that charges crystals and expands the bubble.

Piezo Printheads: The Ink Symphony

Alright, imagine your regular printer, but instead of the usual ink-dropping mechanism, we’re talking about a fancy one that uses what’s called a Drop on Demand Piezo printhead. It’s like the maestro of an ink symphony, orchestrating the perfect ink performance on your paper.

How Piezo Printheads Work – The Behind-the-Scenes Magic

So, inside this printhead, there’s a little ink chamber, kind of like a mini ink reservoir. When it’s showtime and you hit print, the magic begins. Picture this: tiny crystals in the printhead get charged up with piezoelectric vibes. It’s like they’re getting pumped up for a concert.

Now, when these charged-up crystals expand, they create a bubble in the ink chamber. It’s like a tiny ink party happening inside! And when the bubble gets big enough, it pushes the ink out through the nozzles with a burst of energy, creating those tiny droplets that eventually turn into your masterpiece on paper.

Ink Variety – The Printhead Magician:

What’s really cool is that this printhead isn’t a one-trick pony. It can handle different types of inks like a pro – aqueous (that’s water-based), solvent (for those tougher tasks), and even UV-curable (which is like ink that turns into a solid when hit by UV light). It’s like having a versatile artist who can work with watercolors, oils, and even some avant-garde ink types.

Epson’s Piezoelectric Technique: The Crystal Powerhouse

Now, let’s talk about Epson, the big player in this ink game. They’ve got this nifty piezoelectric technique up their sleeves. It’s like they’re charging up tiny crystals in their printheads, making them expand and create that bubble we talked about earlier. It’s like the secret sauce that gives your Epson prints that extra pop!

Why Piezoelectric is Awesome?

So, why should you care about all this ink wizardry? Well, it’s the reason your prints look so darn good! Whether you’re printing a crisp document or a vibrant photo, the Drop on Demand Piezo printhead is the unsung hero making it all happen with precision and flair.

Imagine printing out your favorite photo – the one with you and your pals at the beach. Thanks to this printhead magic, every grain of sand on the shore and every smile in the photo comes out crystal clear. It’s like bringing that sunny day back to life right there on paper.

In a nutshell, Drop on Demand Piezo printheads are like the rockstars of the printing world. They handle different inks, use crystal-powered bubbles, and make sure your prints look top-notch. So, the next time you hit print, just remember, there’s a tiny ink symphony happening inside that printhead, creating your very own masterpiece. Rock on, little printhead!

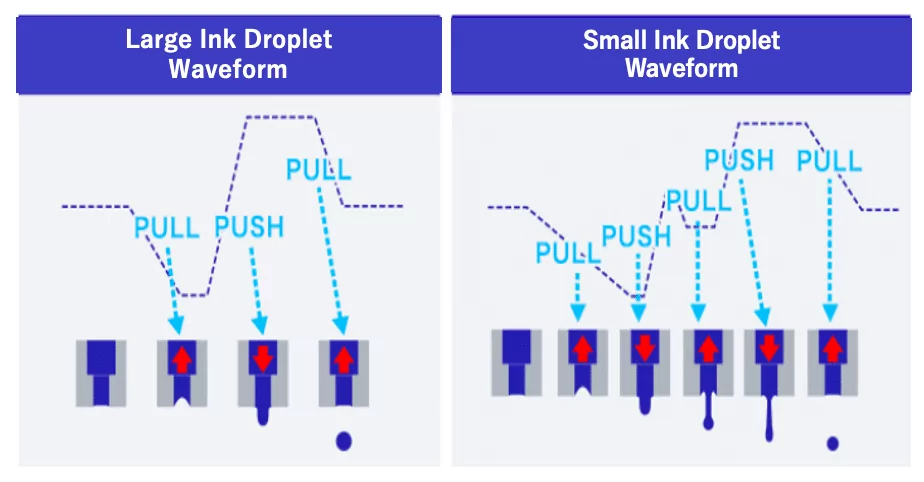

Binary and Grayscale

The overall quality of the output depends on the size of the individual drops of the ink. overall, small drops produce good definition and high-resolution products and are good for text; on the other hand, we can use large droplets for printing large flat areas as they can cover large areas quickly. it is usually common to use a binary approach, every drop being the same size, in bigger printers for a faster result.

Another option is to use greyscale printing which uses different sizes of the ink drops. one of the advantages of mixing smaller and bigger dots is to make it easy to deal with gradients and slight tonal shifts (for example in skyscape or skin tones).

this method also decreases the ink consumptions because of two reasons. First, because some of the dots are fairly small and second because it is much easier to have more smooth gradients with four colors.

There are three basic approaches, which many printheads use a combination of them.

- The first approach is producing different drop sizes by changing the electrical power in charge of generating the drops.

- The second approach is producing a very heavy ink drop that extends when it flies in the air and makes larger and smaller drops.

- The third approach is producing two ink drops quickly that become a single larger drop after merging before reaching the substrate.

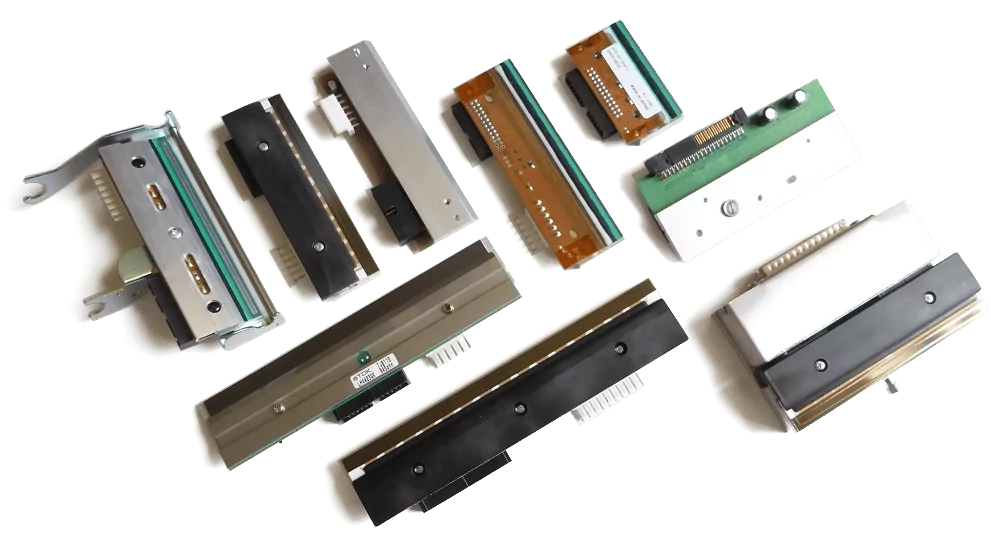

Difference between printheads and ink

A clear distinction exists between the components responsible for depositing ink onto the printing substrate. The ink cartridge serves as the reservoir containing the ink, while the printhead acts as the mechanism through which the ink is dispensed onto the paper.

The ink cartridge, akin to a storage vessel, holds the liquid ink required for printing. It is designed to supply a steady flow of ink to the printhead, ensuring uninterrupted printing operation. The cartridge typically contains specially formulated ink tailored to achieve desired print quality and color accuracy.

On the other hand, the printhead serves as the precision instrument responsible for precisely controlling the deposition of ink onto the paper. It comprises a matrix of microscopic nozzles or channels through which the ink is propelled onto the printing substrate in a controlled manner. The printhead’s intricate design and precise engineering are critical for achieving optimal print resolution, color vibrancy, and image clarity.

In summary, while the ink cartridge functions as the reservoir for ink storage, the printhead serves as the active component responsible for translating digital images into tangible printed output by precisely depositing ink onto the paper. Together, these components form integral parts of the inkjet printing process, working in tandem to produce high-quality prints.

What is a difference between 524 and 1024 printhead?

The speed of the printer is related to the number of the rows of the print head.

For example, the speed of Konica Minolta’s 1024 printhead with multi nozzle is twice the speed of Konica Minolta’s 512 which has a better productivity and achieves 72mm wide printing. However, we can increase the speed of 512 to the same speed of 1024 only by having two rows of printheads.

This way they can have a similar speed. Also the speed of 1024 printhead can be doubled if we increase the number of its rows.

Are large format printers faster with more printheads?

Does it hold true that a large format printer with more printheads operates faster?

The quantity of printheads doesn’t directly impact the speed; rather, the lateral movement of the machine carriage during printing and the firing frequency of the printhead dictate the printing speed. Increasing the number of printheads primarily enhances color and image quality. Incorporating an additional printhead necessitates a redesign of the circuit boards, reinstalling programs, and updating operating software, among other tasks.

The selling price, determined by factors such as costs and labor, can be challenging for customers to accept if compared with the previous selling price. Consequently, manufacturers who are knowledgeable about the machinery typically refrain from stating that increasing the number of printheads will enhance speed.

Advantages and disadvantages of the printheads:

Before delving into the intricacies of various printheads, it’s essential to understand their distinct advantages, disadvantages, and applicable scenarios. The following table offers a comprehensive overview of printheads from prominent manufacturers, highlighting their unique features and suitability for different printing applications. From Epson’s precision-focused approach to Ricoh’s innovative layering technology, each printhead presents distinct advantages and limitations, catering to diverse printing needs. Whether you prioritize precision, speed, or versatility, this pre-description sets the stage for a detailed exploration of printhead characteristics and their implications for print quality and performance.

| Printheads | Advantages | Disadvantages | Applicable |

| Epson | high precision | – slow speed – high failure rate – unclear transition color – unstable life (2-12 months) | – small-volume processing – personalized custom product inkjet printing |

| Konica Minolta | – high precision – fast speed – full transition – color strong color level (gray level change point printing technology) – repairable, plastic shell (insulation) | – plastic shell (not wear-resistant, please pay attention to transportation) – high price | all kinds of materials inkjet |

| Fujifilm (Polaris) | – fast speed – all stainless steel (anti-fall, easy to transport) – repairable and detachable | – low precision – high price | – textile fabrics – wallpaper – other types of spray paint |

| Seiko | – all steel, with an anti-collision steel ring on the nozzle – low price | – many inkjets (high cost) – unclear gradient color (gray-level change-point printing technology) – obvious horizontal stripes in the printed pattern (PS channel) | – no precision requirements – no delicate effects – large-format advertising a class of inkjet printing |

| Ricoh | – high precision – fast speed – full gradient color – a strong sense of layering (gray-level variable point printing technology) – all stainless steel – two colors at one end | High price | All kinds of material printing |

When do you need to replace your printhead?

Cleaning and maintaining the printhead is very important when you use a commercial printer for your business. It is very important to know that printer doesn’t work properly if the printhead is clogged or broken. it is also important to keep in mind that sometimes we need to replace printheads even though they have been taken proper care and maintenance.

when you see the quality of the print outcome is decreasing it means that you need either to clean or replace the printhead. In the following we guide you which one is needed in each situation.

- First, if you see a decrease in the quality of the print, clean the printhead, in some cases the printing system is clogged and it just need a complete cleaning.

- Then you have to run a few cycles of cleaning to get rid of any dried ink in the system or changing the ink cartridge; by following these two steps most of the problems should be solved, but you should replace the printhead if you don’t see any improvement in the quality of the print after the first two steps.

In some printers you can see a warning on the LCD screen if there is any issue regarding the printhead, and in most cases it’s time to change the printhead.

Best deals on inks for your printer

At Compass Systems Co. , we recognize the challenge of sourcing the ideal ink for your printer at a reasonable cost. That’s why our online store provides the most competitive deals on various ink types, including Eco-solvent, Solvent, UV, dye sublimation, and pigment-based in.

What is the difference between printheads for large format printers?

Currently, the market primarily offers seven types of printheads.

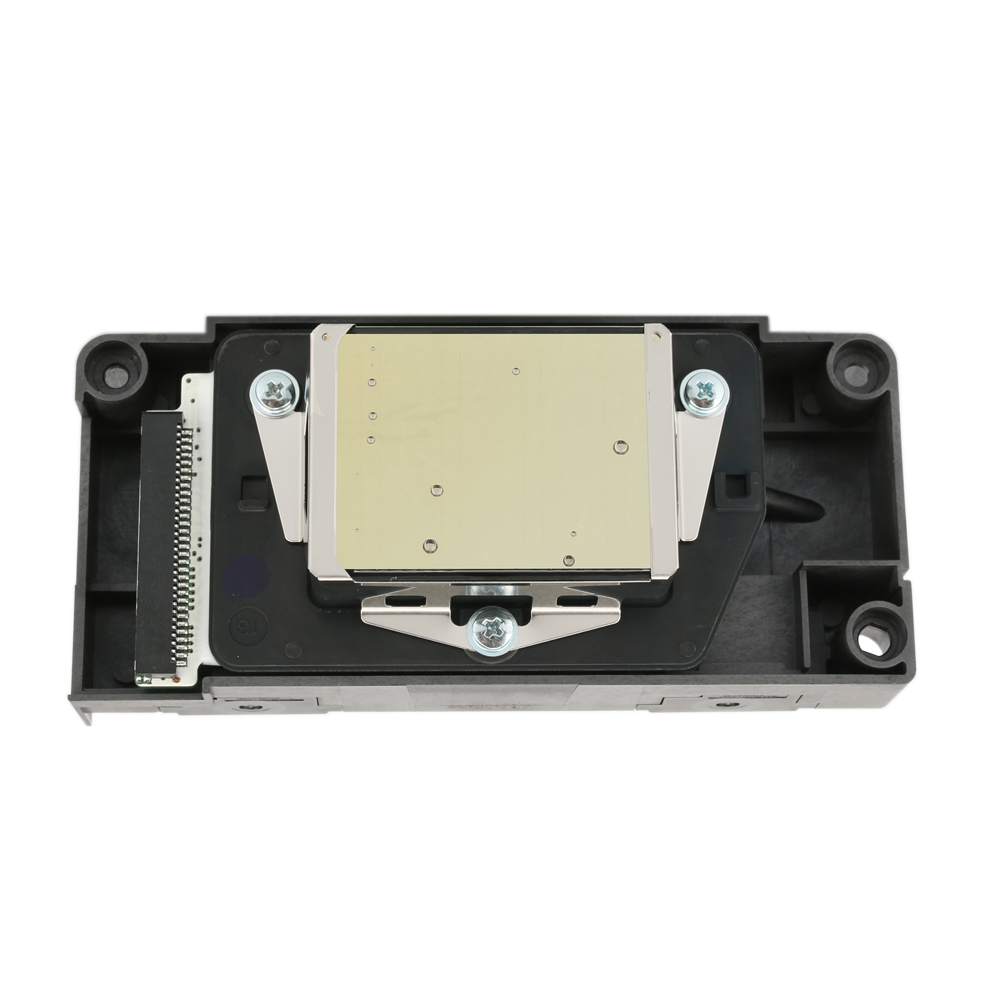

Epson printheads

The Epson printhead Over the years, has emerged as the most widely used type for wide-format inkjet printers. With numerous options available, it’s common for some individuals to feel confused. This comparison highlights several popular options, such as the Epson DX5, DX7, XP600, TX800, Epson 5113, and EPS 3200 head, facilitating a swift decision-making process.

Epson DX5

DX5 stands out as the most stable, widely utilized, and reputable printhead available in the market. However, its notably high price, due to limited supply, has led to a gradual shift towards the adoption of the XP600 printhead in economy-model digital printers.

Epson DX5 Series Eco Solvent Printhead

Invest in the Epson DX5 Series Eco Solvent Printhead for a printing journey that combines precision, efficiency, and Japanese engineering excellence.

Epson DX7

DX7 was once favored as an alternative to the DX5, but it ultimately faced challenges due to its higher price resulting from a shortage of supply.

Epson DX7 Series Water-Based Printhead

Upgrade your printing capabilities with the DX7 Series Water-Based Printhead. This printhead opens up new possibilities for producing stunning, high-quality prints.

Epson TX800(Aka: DX8/ DX10)

TX800 serves as a substitute for the XP600; however, Epson has discontinued production of this model. Consequently, numerous second-hand TX800 units are available in the market. It is advisable to avoid them.

Epson inkjet technology- PIEZO printheads

Epson Piezo printheads operate via piezoelectric elements that contract upon voltage application. Each piezoelectric element is paired with a vibration plate, forming a set. The contraction of the piezoelectric element moves the vibration plate, mechanically generating an inkjet without the need for ink heating. Each printhead features densely arranged rows of these sets, each precisely releasing the appropriate amount of ink to the precise location at a frequency surpassing 40,000 times per second. With no heat generated, this mechatronic technology can accommodate a wide range of ink and media, delivering precise high-speed printing with outstanding durability. Epson employs this technology across its printer range, spanning from home and business to professional, commercial, and industrial applications.

Ricoh PrintHeads

With over 40 years of experience in inkjet technology, Ricoh has established itself as a leader in the field. In recent years, inkjet applications have diversified, encompassing industries such as labeling, packaging, textiles, 3D modeling, and even food and medical applications. Ricoh offers a diverse range of printheads known for their durability, high resolution, and productivity, catering to a wide range of customer needs.

Key attributes of Ricoh inkjet printheads

- Bi-pitch Laminated Piezo Actuator: Inactive poles support active poles at both ends, facilitating stable and precise control of ink discharges by elevating pressure within individual tanks.

- Variable drop volume capability: This technology enables printheads to adjust the effective drop size, facilitating both high resolution and high productivity.

- Ink recirculating structure: The innovative recirculating structure facilitates a continuous ink flow, leading to: 1. Ensuring highly stable jetting performance by preventing nozzle drying and ink particle sedimentation. 2.Minimizing maintenance downtime and ink consumption by averting jetting failure due to nozzle clogging.

- Integrated heater: The integrated heater enables compatibility with high-viscosity inks.

Xaar print heads

Due to the higher standard printhead, it necessitates advanced technology to support the printing platform, as well as elevated standards for printer racks, baseplates, and other components.

When selecting nozzles, factors such as the type of printed fabric, cost estimation, and production efficiency requirements should be taken into account. It’s crucial to also fully consider the cost and durability of replacements, as nozzles are the primary consumable.

Compass Systems Co. is Your Online Store for Printheads, Spare Parts, and Consumables. Are you in search of printheads, spare parts, or consumable products to purchase? Look no further than Compass Systems Co.! Our online store offers a wide selection of models and printing spare parts to meet all your business and personal needs. We’ve got you covered.

Xaar Printheads category

Discover cutting-edge Xaar printheads and explore Inkjet Printing Technology in our Xaar category.

How to clean inject printheads?

Cleaning inkjet printheads is like giving your printer a spa day to keep it in tip-top shape. Just like how you need to take care of your car with regular maintenance, your printer needs a little TLC too, especially when it comes to those finicky printheads. So, let’s dive into the world of printhead maintenance and learn how to keep those ink flowing smoothly.

Understanding Printhead Clogs:

First things first, let’s talk about printhead clogs. You know those annoying streaks or missing lines that sometimes show up on your prints? Yeah, those are caused by printhead clogs. It’s like your printer’s way of saying, “Hey, I need a little cleaning here!”

Types of Clogs:

Printhead clogs come in different flavors – there’s the simple ones that can be fixed with a quick cleaning cycle, the stubborn ones that need a bit more elbow grease, and then there are the hardcore ones that require some serious intervention.

Simple Clogs:

Think of simple clogs like a minor hiccup. Usually, running a cleaning cycle on your printer can clear these up. It’s like giving your printer a little shake to wake it up.

Stubborn Clogs:

Now, if your printer is being a bit stubborn and the regular cleaning cycles aren’t doing the trick, it’s time to bring out the big guns. You might need to use warm water or a special cleaning solution to break up dried ink and get those printheads back in action.

Hardcore Clogs:

And then there are the hardcore clogs – the ones that just won’t budge. For these, you might have to roll up your sleeves and take the printhead assembly out of the printer. It’s like giving your printer a full spa treatment to get rid of those stubborn clogs once and for all.

Cleaning Your Printhead – Step by Step:

Now, let’s talk about how to actually clean those printheads. It’s not as complicated as it sounds, I promise!

- Start by running a printhead purge from your printer’s menu. Think of it like flushing out the gunk from your printer’s system.

- If that doesn’t do the trick, you might need to prime the printhead by gently pumping ink through it. It’s like giving your printer a little boost to get things moving again.

- For those stubborn clogs, you can try using a cleaning solution or warm water to break up dried ink. Just be careful not to damage the printhead in the process.

- Finally, give everything a good wipe down with a lint-free cloth to make sure there’s no leftover ink or particles hanging around.

- Test Your Printer: Once you’re done cleaning, it’s time to put your printer to the test. Print out a test page to see if those clogs are gone for good. If not, don’t worry – you can always reach out to a professional for some extra help.

And there you have it – your guide to keeping your inkjet printer happy and clog-free. With a little regular maintenance, you can keep those printheads running smoothly and your prints looking pristine. Happy printing!

Cleaning the Printhead Manually

When the automatic self-cleaning function of your printer falls short, resorting to manual cleaning becomes necessary. Follow these steps meticulously to effectively clean your printhead:

- Gather Your Supplies: Before embarking on the cleaning process, ensure you have the necessary supplies at hand. You’ll need water, a paper towel, and isopropyl alcohol. Avoid cleaners containing harsh chemicals like bleach, as they can inflict substantial damage on your printer, potentially exacerbating issues in the future.

- Turn Off Your Printer: Prior to commencing the cleaning procedure, power down your printer manually. Ensure it is completely switched off, then disconnect the power cord from the wall outlet. This precautionary measure is crucial when dealing with electronics and liquid substances to minimize the risk of fire hazards.

- Remove Cartridges and Printhead: Carefully remove the ink cartridges one by one from the printhead. Avoid exerting excessive force when removing cartridges, as each printer model typically has a specific procedure for their safe removal. Once the cartridges are removed, delicately extract the printhead, which will be submerged in the cleaning solution later.

- Prepare Printhead Cleaning Solution: Create a suitable cleaning solution for your printhead by mixing equal parts of isopropyl alcohol and water. This concoction effectively cleans without causing damage to the printhead or printer. Pour the solution into a shallow bowl, ensuring it does not overflow.

- Dip and Dry Printhead: Submerge the printhead into the cleaning solution for a maximum of two minutes. Prolonged exposure may harm the printhead, while insufficient time may render the cleaning ineffective. After two minutes, carefully remove the printhead from the solution and pat it dry with a paper towel.

- Reassemble and Test Print: Once the printhead is thoroughly cleaned and dried, reinsert it into the printer, ensuring proper alignment. Reinstall the ink cartridges securely. Proceed to perform a test print to verify that the printer functions correctly, with consistent ink flow and high-quality print output. If despite thorough cleaning, issues persist with the printhead, it could indicate underlying problems requiring professional attention. In such instances, it is advisable to seek assistance from a qualified technician to diagnose and rectify the issue effectively.

The surge in popularity of inkjet printers, owing to their affordability and improved capabilities, has led to a noticeable increase in their usage. As more individuals incorporate inkjet printers into their daily routines, encountering a common issue becomes inevitable – printhead clogging.

The Best Material For Inkjet Printhead Cleaning?

Previously, the prevailing solution offered by printer companies and service centers was the replacement of the entire printhead assembly, a costly endeavor. However, before resorting to this drastic measure, an alternative approach involves attempting to manually clean the printhead.

Understanding Printhead Clogs:

Printhead clogs primarily occur due to the accumulation of ink droplets in the nozzles, leading to blockages that hinder the passage of subsequent ink droplets. This perpetuates a cycle of accumulation, eventually obstructing the entire ink passage.

Addressing Printhead Blockages:

Identified by white lines on prints or incomplete nozzle patterns, the onset of a blockage necessitates running cleaning cycles as outlined in printer manuals. If standard cleaning cycles prove ineffective, detaching and chemically cleaning the printheads is recommended.

Exploring Printhead Cleaning Solutions:

Various chemicals, including acetone, isopropyl alcohol, water, and ammonia, are commonly suggested for printhead cleaning. However, each presents its own drawbacks and risks, raising questions about their suitability for this purpose.

- Water: While unfiltered water can exacerbate nozzle clogging due to suspended impurities and dissolved salts, even distilled water’s efficacy in dissolving ink particles is limited.

- Ammonia: While diluted ammonia may be used for cleaning, improper dilution poses risks to the printhead’s internal components, rendering it an unreliable solution.

- Isopropyl Alcohol (IPA): IPA offers temporary relief by dissolving solidified ink to some extent. However, its compatibility with printhead materials is questionable, potentially leading to damage.

- Acetone: Although acetone effectively dissolves solidified ink, its aggressive nature poses a significant risk of damaging printhead components.

conclusion

Printheads, they’re like the unsung heroes of printing, right? They’re the ones responsible for getting those ink droplets onto your paper, whether you’re printing out your vacation photos or that important report for work.

We learned about different types of printheads – from the thermal ones that use heat to vaporize ink, to the piezo ones that use electric charges to create bubbles. Each type has its own quirks and specialties, but they all work together to give you those crisp, clear prints And let’s not forget about picoliters – those tiny little units that measure the volume of ink droplets. Who knew something so small could have such a big impact on print quality?

But hey, it’s not all rainbows and unicorns. Printheads can get clogged up, causing all sorts of printing woes. Luckily, we also learned some handy tips for keeping those printheads squeaky clean and ready to go.

So, whether you’re printing out a masterpiece or just another boring report, remember to give a little nod of appreciation to those hardworking printheads. After all, they’re the ones making sure your prints come out looking top-notch every time.

No comment